Unveiling the Power of WMS in London’s Commercial Warehouse Storage: FAQs and Insights

Warehouse Management Systems (WMS) in London, the bustling heart of the United Kingdom’s logistics industry, are the unsung heroes of efficient and organized storage facilities. From the labyrinthine alleys of historic warehouses nestled along the Thames to the cutting-edge distribution centers on the city’s outskirts, WMS plays a pivotal role in streamlining operations and ensuring that goods flow seamlessly from entry to exit. But what exactly is WMS in a warehouse in London, and how does it revolutionize the way businesses manage their inventory? Let’s delve into this essential component of modern logistics and discover how it’s transforming the warehousing landscape in the UK capital.

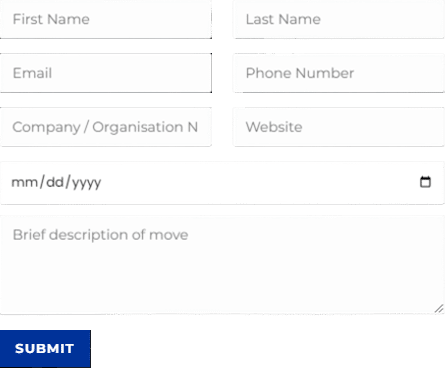

Discuss Your Move Today

Give us a call at 0208 575 1133, or use the form below to book your service.

This page supports our content about commercial warehouse storage and you can find other in-depth information about What is WMS in a warehouse in London by following this link or answers to related questions like What are the five warehouse operations in London if you click here.

Before we dive into the frequently asked questions about commercial warehouse storage in London, let’s first establish a clear understanding of the key aspects and considerations surrounding this essential component of the city’s logistics landscape.

What are the four components of a warehouse system in London?

In a commercial warehouse storage system in London, the four key components typically include:

These components collectively contribute to the effective functioning of a commercial warehouse system in London, allowing businesses to manage their inventory and operations efficiently.

Storage Infrastructure: This encompasses the physical storage facilities, such as racks, shelves, and pallets, tailored to the specific needs of the goods being stored.

Warehouse Management Software (WMS): WMS is essential for efficient inventory control, order processing, and tracking goods within the facility.

Material Handling Equipment: Forklifts, conveyors, and other equipment are vital for moving goods efficiently and safely within the warehouse.

Personnel: A skilled workforce, including warehouse operators and managers, ensures smooth operations, from receiving goods to dispatching orders.

Why do warehouses need WMS in London?

Warehouses in London require Warehouse Management Systems (WMS) for several key reasons:

In London’s competitive commercial warehouse storage landscape, WMS is essential for cost-effective, accurate, and efficient warehouse operations, ultimately contributing to business success.

Efficiency: WMS optimizes inventory management, reducing storage costs and minimizing handling errors, leading to cost savings.

Accuracy: It enhances inventory accuracy, reducing the risk of stockouts, overstocking, and associated financial losses.

Productivity: WMS streamlines operations, improving order processing times and increasing throughput, ultimately boosting productivity.

Customer Satisfaction: With WMS, warehouses can fulfill orders faster and with fewer errors, leading to higher customer satisfaction and repeat business.

Data Insights: WMS provides valuable data and analytics, enabling better decision-making for inventory control and process improvements.

What technology is used in warehouses in London?

Warehouses in London utilize a range of technologies to enhance operations, including:

Investing in these technologies in an industrial packhouse reserve in London helps warehouses operate efficiently, reduce costs, and meet the demands of modern logistics.

Warehouse Management Systems (WMS): WMS software optimizes inventory control, order processing, and overall warehouse management.

RFID Technology: RFID tags and readers track inventory items, improving accuracy and efficiency.

Automation and Robotics: Automated conveyor systems and robotics assist with material handling and order fulfillment.

Barcoding Systems: Barcodes and scanners are used for quick and accurate inventory tracking.

Advanced Security Systems: CCTV cameras, access control, and alarm systems help protect valuable goods.

Inventory Control Software: Software solutions aid in real-time inventory monitoring and demand forecasting.

Forklift Technology: Advanced forklifts with sensors and automation improve safety and efficiency.

Energy-Efficient Lighting: LED lighting and energy management systems reduce operating costs.

How does RFID work in a warehouse in London?

RFID (Radio-Frequency Identification) technology in a corporate asset warehousing setting in London operates by using RFID tags attached to assets. These tags contain a unique identifier and can store information about the asset. RFID readers and antennas in the warehouse emit radio signals, which activate the RFID tags. When activated, the tags transmit their information back to the reader, allowing for real-time tracking and monitoring of assets. This technology enhances inventory accuracy, reduces manual data entry, and enables efficient asset management, ultimately saving businesses time and money in their corporate asset warehousing operations in the UK capital.

What are the disadvantages of a smart warehouse in London?

While smart warehouses in London offer numerous benefits, they also come with certain disadvantages, including:

Balancing the advantages and disadvantages is essential when considering the adoption of smart technology in commercial warehouse storage in London, ensuring it aligns with specific business goals and resources.

High Initial Costs: Implementing smart technology requires significant upfront investments in infrastructure, software, and training, which can be a financial burden.

Complexity: Managing and maintaining the various interconnected technologies can be complex, requiring skilled personnel and ongoing support.

Security Risks: Smart systems can be vulnerable to cybersecurity threats, potentially exposing sensitive data and disrupting operations.

Dependence on Technology: Overreliance on technology may pose challenges during system failures or downtime, impacting warehouse productivity.

Skill Requirements: Workforce may need additional training to operate and troubleshoot advanced systems effectively.

Integration Challenges: Integrating new technology with existing warehouse systems can be challenging and time-consuming.

Upkeep Costs: Ongoing maintenance and upgrades can be costly, impacting the long-term operational budget.

What is an IoT warehouse in London?

An IoT (Internet of Things) warehouse in London refers to a commercial warehouse storage facility that utilizes IoT technology to enhance operations. IoT sensors and devices are strategically placed throughout the warehouse to collect data on various aspects, such as inventory levels, temperature, humidity, and equipment status. This real-time data is then transmitted over the internet to a central system, allowing warehouse managers to monitor and manage the facility remotely. IoT warehouses in London aim to improve efficiency, reduce costs, and optimize inventory management, ultimately contributing to more streamlined and cost-effective commercial storage operations in the UK capital.

What is the difference between warehouse and advanced warehousing in London?

The primary difference between a standard warehouse and advanced warehousing in London lies in the level of technology and automation. While a traditional warehouse typically relies on manual processes for tasks like inventory management and order fulfillment, advanced warehousing leverages cutting-edge technology and automation solutions.

In advanced warehousing:

In summary, advanced warehousing in London incorporates technology and automation to enhance efficiency, accuracy, and adaptability, making it a more advanced and cost-effective solution compared to traditional warehousing.

Technology Integration: Advanced warehouses use Warehouse Management Systems (WMS), RFID technology, IoT sensors, and automation systems to optimize operations.

Efficiency: Advanced warehousing focuses on increasing operational efficiency through real-time data analysis, process automation, and streamlined workflows.

Accuracy: Automation reduces human error, improving inventory accuracy and order fulfillment.

Cost Savings: While advanced warehousing may have higher upfront costs due to technology investments, it can lead to long-term cost savings through improved efficiency.

Scalability: Advanced warehousing systems are often more adaptable to changing business needs and can scale operations efficiently.

What is the difference between a warehouse control system and WMS in London?

The main difference between a Warehouse Control System (WCS) and a Warehouse Management System (WMS) in London lies in their respective functions and focus within a commercial warehouse storage environment.

In summary, a Warehouse Management System (WMS) primarily deals with managing warehouse processes and optimizing inventory, while a Warehouse Control System (WCS) is more focused on automating and controlling the physical movements of goods within the warehouse. Both systems can play complementary roles in enhancing the efficiency and performance of commercial warehouse storage operations in London.

Warehouse Management System (WMS):

Function: WMS primarily focuses on managing and optimizing warehouse processes, such as inventory tracking, order management, and workforce management.

Key Features: WMS handles tasks like inventory accuracy, order picking and packing, and often interfaces with other business systems like accounting and customer relationship management (CRM) software.

Efficiency and Accuracy: It aims to enhance overall warehouse efficiency and accuracy, ensuring that products are stored, picked, and shipped correctly.

Cost Savings: By streamlining processes, WMS helps reduce operating costs and improve customer service.

Example Cost: Implementation costs for a WMS system in London can range from thousands to tens of thousands of pounds, depending on the complexity.

Function: WMS primarily focuses on managing and optimizing warehouse processes, such as inventory tracking, order management, and workforce management.

Key Features: WMS handles tasks like inventory accuracy, order picking and packing, and often interfaces with other business systems like accounting and customer relationship management (CRM) software.

Efficiency and Accuracy: It aims to enhance overall warehouse efficiency and accuracy, ensuring that products are stored, picked, and shipped correctly.

Cost Savings: By streamlining processes, WMS helps reduce operating costs and improve customer service.

Example Cost: Implementation costs for a WMS system in London can range from thousands to tens of thousands of pounds, depending on the complexity.

Warehouse Control System (WCS):

Function: WCS is primarily responsible for controlling and automating the physical aspects of the warehouse, including conveyors, sorters, and other material handling equipment.

Key Features: WCS coordinates the movement of goods within the warehouse, ensuring that they are transported efficiently and in accordance with operational priorities.

Efficiency and Automation: WCS focuses on automation and real-time control, optimizing the flow of goods through the warehouse.

Cost Savings: It can lead to cost savings by reducing labor requirements and improving throughput.

Example Cost: The cost of implementing a WCS in London can vary widely based on the complexity of the system and the size of the warehouse but may range from thousands to hundreds of thousands of pounds.

Function: WCS is primarily responsible for controlling and automating the physical aspects of the warehouse, including conveyors, sorters, and other material handling equipment.

Key Features: WCS coordinates the movement of goods within the warehouse, ensuring that they are transported efficiently and in accordance with operational priorities.

Efficiency and Automation: WCS focuses on automation and real-time control, optimizing the flow of goods through the warehouse.

Cost Savings: It can lead to cost savings by reducing labor requirements and improving throughput.

Example Cost: The cost of implementing a WCS in London can vary widely based on the complexity of the system and the size of the warehouse but may range from thousands to hundreds of thousands of pounds.

What is a decentralized warehouse in London?

A decentralized warehouse in London, within the context of an industrial packhouse reserve, refers to a distribution and storage system where goods are stored in multiple smaller facilities or locations rather than a single centralized warehouse. These smaller warehouses, often strategically positioned closer to end customers or production areas, allow for quicker order fulfillment and reduced transportation costs. Decentralized warehousing can enhance supply chain agility and responsiveness while optimizing inventory management. It enables businesses in London to adapt to fluctuating demand and improve overall efficiency in the storage and distribution of goods, potentially resulting in cost savings in the long run.

What technology is used to improve warehouse efficiency in London?

Various technologies are employed in London’s industrial packhouse reserves to enhance warehouse efficiency, including:

While the specific technologies used may vary, their collective implementation in industrial packhouse reserves in London aims to optimize operations, reduce costs, and enhance overall efficiency, contributing to a competitive advantage in the supply chain.

Warehouse Management Systems (WMS): WMS software streamlines inventory control, order processing, and workflow management, improving overall efficiency.

Automation and Robotics: Automated systems and robotics handle tasks like picking, packing, and material handling, reducing manual labor and increasing productivity.

RFID Technology: RFID tags and readers provide real-time visibility into inventory, reducing errors and enhancing efficiency.

IoT Sensors: Internet of Things sensors monitor temperature, humidity, and equipment status, ensuring optimal conditions and minimizing disruptions.

Data Analytics: Advanced analytics tools provide insights into warehouse operations, helping identify areas for improvement and efficiency gains.

Voice and Pick-to-Light Systems: These systems guide warehouse workers, reducing errors and speeding up order fulfillment.

Advanced Shelving and Storage Solutions: High-density storage systems maximize space utilization and accessibility.

How do you do warehouse automation in London?

Warehouse automation in London, within the context of an enterprise storehouse depot, involves implementing advanced technologies and processes to optimize operations. Here’s a concise overview of how warehouse automation is achieved:

By strategically implementing warehouse automation technologies and processes, businesses in London can enhance productivity, reduce errors, and improve the overall efficiency of their enterprise storehouse depot, potentially leading to cost savings and competitive advantages.

Evaluate Needs: Start by assessing your specific operational needs, including inventory volume, order processing speed, and workforce capabilities.

Invest in Technology: Procure automation technologies such as conveyor systems, automated storage and retrieval systems (AS/RS), robotics, and Warehouse Management Systems (WMS).

Integrate Systems: Ensure seamless integration of automation systems with your existing infrastructure and software, allowing for efficient data flow and coordination.

Automate Material Handling: Implement automated equipment for tasks like goods transportation, sorting, and stacking, reducing manual labor.

Utilize Robotics: Deploy robots for picking, packing, and inventory management, improving accuracy and speed.

Implement WMS: Leverage WMS to control and optimize automated processes, ensuring efficient inventory management and order fulfillment.

Train Workforce: Train staff to work alongside automation systems, monitor operations, and perform maintenance.

Continuous Improvement: Regularly analyze data and performance metrics to identify areas for further automation and efficiency enhancement.

Cost Considerations: Budget for initial investments, ongoing maintenance, and potential cost savings from increased efficiency.

What is an automated warehouse used for in London?

An automated warehouse in London, particularly within the context of an industrial packhouse reserve, is used for efficient and streamlined storage, retrieval, and distribution of goods. It employs advanced automation technologies, such as robotics, conveyor systems, and Warehouse Management Systems (WMS), to:

Overall, automated warehouses in London play a pivotal role in modernizing supply chain operations, enhancing customer service, and ultimately contributing to the competitiveness of businesses in the industrial packhouse reserve sector.

Optimize Efficiency: Automate tasks like order picking, packing, and material handling to reduce manual labor and improve operational efficiency.

Enhance Accuracy: Minimize human errors in inventory management and order fulfillment, ensuring greater precision in stock levels and deliveries.

Increase Throughput: Speed up the movement of goods, allowing for higher order throughput and quicker response to customer demands.

Maximize Space: Utilize storage space efficiently, often through high-density storage solutions, reducing the need for larger warehouse facilities.

Improve Traceability: Employ technologies like RFID and barcode systems for real-time tracking and traceability of inventory.

Reduce Costs: While there are upfront costs for automation implementation, it can lead to long-term cost savings through improved efficiency and reduced labor expenses.

What are the advantages of a smart warehouse in London?

A smart warehouse in London, especially within the context of an industrial packhouse reserve, offers several significant advantages, including:

In summary, a smart warehouse in London can contribute to cost savings, operational excellence, and improved competitiveness, making it a strategic investment for businesses in the industrial packhouse reserve industry.

Enhanced Efficiency: Automation and real-time data analysis optimize operations, leading to faster order fulfillment and reduced labor costs (£) over time.

Improved Accuracy: Automation reduces the risk of human errors in tasks like inventory management, enhancing order accuracy.

Cost Savings: While initial investment costs can be significant, smart warehouses can result in long-term cost savings through reduced labor expenses and efficient resource allocation.

Optimal Space Utilization: Advanced storage solutions maximize space utilization, potentially reducing the need for larger warehouse facilities.

Enhanced Traceability: Technologies like RFID and IoT sensors provide real-time tracking and traceability of inventory, improving visibility across the supply chain.

Better Decision-Making: Data analytics tools offer insights into warehouse performance, enabling data-driven decision-making and process improvements.

Adaptability: Smart warehouses are more adaptable to changing business needs and market demands, offering flexibility and scalability.

Competitive Edge: Improved efficiency and customer service can provide a competitive advantage in the industrial packhouse reserve sector.

In conclusion, the realm of commercial warehouse storage in London is a dynamic and indispensable part of the city’s thriving logistics industry. By now, you’ve gained insights into what WMS in a warehouse in London entails, and how it serves as the linchpin in the seamless management of inventory, ensuring businesses operate with unparalleled efficiency. Whether you’re navigating the historic warehouses along the Thames or embracing the cutting-edge technologies in modern distribution centers, understanding the role of WMS in this bustling metropolis is paramount. We hope these FAQs have shed light on this crucial aspect of London’s logistical infrastructure, enabling you to navigate the intricate world of commercial warehouse storage with confidence and success.

Ready to optimize your warehouse operations in London with cutting-edge WMS solutions? Contact Universal Commercial Relocation today at 0208 575 1133, and let’s elevate your logistics to new heights!