Mastering Warehouse Storage in London: Strategies for Success Unveiled

Warehousing in the bustling heart of London is a symphony of precision and strategy, where space is a coveted commodity, and logistics reign supreme. Whether you’re a seasoned logistics professional navigating the intricacies of a vast distribution centre or an entrepreneur seeking to optimise storage solutions, understanding how to store things in a warehouse in London is paramount. In this dynamic city, where historic streets intertwine with cutting-edge technology, the art of warehousing is a crucial element in the tapestry of commerce. Let’s embark on a journey through the realm of warehousing, exploring the methods and strategies that make this metropolis an epicentre of efficient storage and distribution.

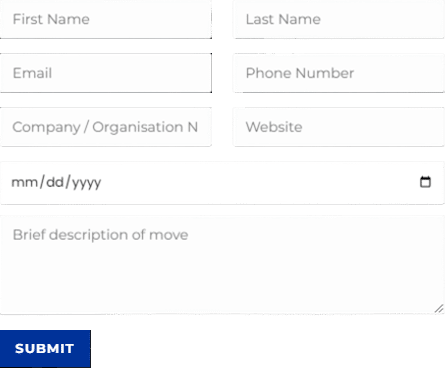

Discuss Your Move Today

Give us a call at 0208 575 1133, or use the form below to book your service.

This page supports our content about corporate asset warehousing and you can find other in-depth information about What is KPI for warehouse capacity in London by following this link or answers to related questions like What is the most common mass storage device in London if you click here.

Before we delve into the FAQs about corporate asset warehousing in London, let’s unravel the intricacies of effective storage methods in this bustling metropolis.

How do you store inventory in a warehouse in London?

Storing inventory in a warehouse in London, particularly in an industrial packhouse reserve, involves several key steps:

By following these steps, businesses can efficiently store inventory in a warehouse in London, ensuring accessibility, security, and cost-effectiveness in managing their industrial packhouse reserve.

Organisation: Implement a systematic storage plan, categorising inventory by type, size, and frequency of use.

Racking Systems: Utilise sturdy racking and shelving to maximise vertical space, optimising storage capacity per pound.

Labelling: Clearly label each item or pallet, including essential information like product name, SKU, and expiry date.

Inventory Management Software: Invest in software to track inventory levels, reorder points, and monitor stock movements.

Stock Rotation: Implement a first-in, first-out (FIFO) or last-in, first-out (LIFO) system to ensure that older inventory is used before newer stock.

Security Measures: Implement security protocols, including CCTV surveillance and access controls, to safeguard valuable inventory.

Climate Control: Maintain suitable temperature and humidity levels for specific items, such as perishable goods.

Regular Audits: Conduct periodic audits to ensure accurate inventory counts and identify any discrepancies.

Efficient Layout: Design a layout that facilitates smooth movement of goods, reducing the time and effort required for picking and packing.

Space Optimization: Continuously assess storage needs and adjust configurations to maximise space and minimise costs per pound of stored inventory.

How do warehouses keep track of inventory in London?

Warehouses in London employ various methods to efficiently keep track of inventory, ensuring accurate records and smooth operations:

By employing these methods, warehouses in London can effectively keep track of inventory, reduce errors, improve efficiency, and provide reliable service to their clients in commercial warehouse storage.

Barcoding and Scanning: Using barcodes and handheld scanners to track items, update inventory levels, and reduce errors in data entry.

Inventory Management Software: Implementing specialised software to automate tracking, providing real-time visibility into stock levels, and generating reports for analysis.

RFID Technology: Utilising Radio-Frequency Identification (RFID) tags to track items with greater precision, enabling automated inventory management.

Regular Audits: Conducting routine physical counts and reconciling them with digital records to identify and rectify discrepancies.

Stock Control Procedures: Implementing protocols like First-In, First-Out (FIFO) or Last-In, First-Out (LIFO) to manage inventory flow efficiently.

Reorder Point Systems: Establishing reorder points to trigger automatic restocking when inventory reaches predefined levels.

Zone Picking: Organising the warehouse into zones and assigning staff to specific areas for faster and more accurate order fulfilment.

ABC Analysis: Categorising inventory into A, B, and C groups based on importance, allowing for prioritised management efforts.

Cycle Counting: Conducting frequent, small-scale inventory counts to maintain data accuracy without the need for full-scale audits.

Employee Training: Providing training to warehouse staff to ensure they understand and adhere to inventory management procedures.

In closing, the art of storing things in a warehouse in London is a dynamic blend of tradition and innovation, where every square foot counts and efficiency reigns supreme. As we’ve journeyed through the strategies and methods that make this city an epicentre of warehousing excellence, one thing becomes abundantly clear: London’s warehouses are more than mere storage spaces; they are the lifeblood of commerce in this vibrant metropolis. Whether you’re navigating the historic streets of the West End or leveraging cutting-edge technology in the Docklands, the quest for efficient storage remains paramount. So, as you embark on your warehousing endeavors in this bustling city, armed with knowledge and strategy, remember that in London, the answer to How do you store things in a warehouse? is a symphony of precision and a testament to the art of commerce.

For expert guidance on optimizing your warehouse storage in London and achieving unparalleled efficiency, contact Universal Commercial Relocation today at 0208 575 1133. Transform your storage solutions!